Our Services

Experience your journey to excellence with Kalom Engineering. Our seasoned team, rooted in years of expertise, navigates the complexities of the Oil & Gas and Maritime industries with precision

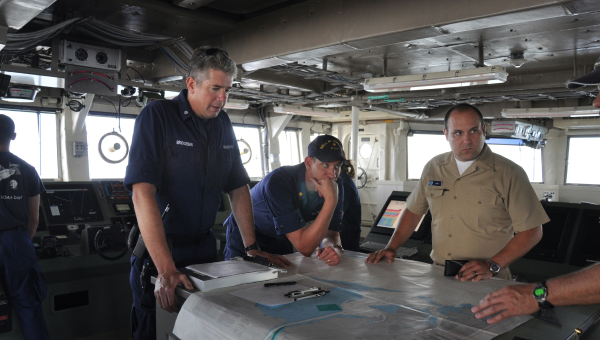

Maritime

Engineering

Trading

Explore Our Services

We collaborate with leading EPC Contractors to execute a complete range of service solutions across the value chain in Oil & Gas Industry and beyond.

Project Execution Gates & Deliverables

Experience your journey to excellence with Kalom Engineering. Our seasoned team, rooted in years of expertise, navigates the complexities of the Oil & Gas and Maritime industries with precision

Phase 1

Conception

This phase explores project feasibility, outlines preliminary designs, and sets project objectives

Phase 2

Pre-Feed

Pre-Front End Engineering Design involves refining project concepts and conducting initial design studies

Phase 3

Feed

The Front End Engineering Design phase is where detailed planning takes place, including technical and engineering specifications

Phase 4

Ded

In this Detailed Design phase, we execute the project based on the detailed plans, focusing on precision and adherence to standards

Engineering design process & QA/QC

Stringent Design Review Cycles

Our design process includes rigorous review cycles at each stage, ensuring that every aspect of the project meets the highest standards of quality and functionality. Our team meticulously evaluates the design for efficiency, safety, and reliability, incorporating feedback and improvements continuously.

This iterative process guarantees that our final product is not only compliant with industry standards but also aligns perfectly with client expectations.

Electronic Document Management System

At the heart of our operations is an electronic document management system (EDMS). This system ensures efficient processing, storage and retrieval of project documents. It enhances collaboration, maintains version control and guarantees the security and integrity of our project documentation, which is essential when managing complex engineering projects

Internal Engineering Procedures

Our internal engineering procedures are the backbone of our project execution strategy. They are meticulously crafted to ensure consistency, quality, and adherence to industry standards. These procedures cover everything from project initiation to delivery, encompassing risk management, quality control, and resource allocation, thereby ensuring seamless project execution.

Vendor & 3rd party Interface

Our Vendor and 3rd Party Interface focuses on establishing robust, collaborative relationships with external partners. This involves stringent selection criteria, continuous performance monitoring, and a strong emphasis on clear communication and compliance with industry standards. Through this interface, we ensure that all third-party interactions align with our organizational goals and quality expectations.

Value Engineering Practices

Our value engineering practices are focused on optimizing the value of each project. We achieve this by evaluating cost versus function, aiming to maximize functionality while minimizing costs. These practices involve innovative thinking, sustainable material selection, and efficient construction techniques, ensuring the delivery of high-quality, cost-effective engineering solutions.